-

Introduction

Most enterprises in the manufacturing sector are facing a crucial problem during new product development or component procurement: the quotation for the unit price by small-batch CNC trial production is too high, while directly entering mass production involves huge financial risks and market uncertainties. Such a price gap usually does not result from arbitrary pricing by suppliers but from a lack of profound understanding about the cost structure of CNC Machining Services, especially the allocation mechanisms of fixed and variable costs.

This article will analyze the composition principles of the CNC machining cost, incorporating real-world Supplier Case Studies to reveal practical paths to cost optimization from prototype making to large-scale production, demonstrating how scientific planning can tap economies of scale. Mastering the following key dimensions will be essential for developing an effective procurement strategy.

How does a pricing model for CNC machining services work in real life?

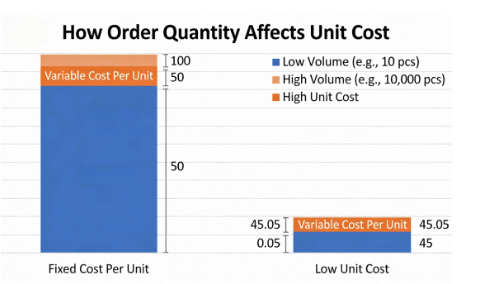

The quotation for CNC machining services is basically derived through a simple, clearly understandable formula: Total Price = One-time Fixed Costs + (Unit Variable Cost × Quantity). Fixed costs are those unrelated to the volume of production and include items such as programming, process design, preparation of fixtures, and first-article inspection. These are one-time investments to start the production. Variable costs vary directly with the amount produced. They include material, machine operational time, labor, tool wear, and energy consumption. Thus, in the case of small batches, high fixed costs are divided among a few units, which results in a high unit price. As the volume of production increases, the fixed costs become highly diluted, and unit variable costs may also decrease due to the efficiency effect, which yields a substantially lower price per part.

For simplification, the table below shows a simplified cost breakdown for an aluminum part at various volumes of production.

Cost Component Small Batch (10 pcs) Large Batch (10,000 pcs) Notes One-time Fixed Costs $500 $500 Programming, fixtures, first-article inspection. Unit Variable Cost $50/part $45/part Material, machining time, tooling (efficiency gains reduce cost in large batches). Total Cost 500+(50 × 10) = $1,000 500+(45 × 10,000) = $450,500 – Unit Cost $100/part $45.05/part Dilution of fixed costs is the key differentiator. This pricing mechanism works in line with the models used by industrialists like the Industry Assessment Center (IAC) of the U.S. Department of Energy, such as the model for fixed and variable costs developed by authorities in the manufacture cost analysis field. Comprehending this model is just the first step; the second would be to ascertain what exactly drives the final CNC machining price.

What main factors deeply affect the final price of CNC machining?

Many variables are involved, and these interact to develop the final cost. Only by understanding systematically the factors involved can there be effective cost control.

Material Cost and Selection

Material is one of the biggest cost drivers. As an example, stainless steel CNC machining services are more expensive compared to regular aluminum due to the material cost itself and difficult machining characteristics that increase tool wear and extend processing times. The cost raises further with titanium CNC machining, when the raw material price can be 5-8 times higher than that of aluminum, its poor thermal conductivity and high strength forcing the machining speeds slower, thus speeding up the tool wear even more. For understanding how different materials are trading off in performance versus cost, a comprehensive Advanced Materials Guide should be consulted.

Part Geometry and Specification Requirements

That is to say, the complexity of the part design and the stringency of its specifications will be in direct proportion with the machining difficulty and time.

- Geometric Complexity:

Features such as deep holes, greater than 5 times the diameter in depth, thin walls, less than 1mm, micro-threads, and complex contoured surfaces The programming will be increasingly sophisticated, requiring specialized tools and cautious machining strategies that may increase costs by 30% to 50% over and above that of more straightforward geometries.

- Tolerances and Surface Finish:

Exponential increases in cost arise in relation to precision. The need to change from standard ±0.1 mm to high precision ±0.005 mm may require higher-end machines, additional finishing operations, and more frequent inspections that drastically drive up machining time and cost. Superior surface finishes also require additional post-processing steps, usually in the form of polishing or specialized anodizing, adding to the overall expense.

Order Quantity and Post-Processing Needs

As explained in the price model, order quantity is the first order derivative of unit cost due to the shared of fixed costs. Moreover, secondary processes such as heat treatment to improve strength, anodizing for corrosion protection and good looks, or painting involve additional stages and costs. A supplier’s material management and process expertise is vital in controlling such factors effectively.

How does high-volume production achieve significant unit cost reduction?

Transitioning to high volume CNC machining frees up a significant economy of scale. The most obvious advantage is that fixed costs are highly diluted over a large number of units, where their impact becomes minimal or nil. Next, bulk purchase of raw materials often attracts a handsome discount. However, the most sizable gains come from process optimization. The ability to invest in dedicated fixturing, which enable quicker load/unload and multi-part machining, slashes cycle times per part. Second, better tool paths and the implementation of more efficient machining techniques further help save time.

The basic things are further amplified by the principles of Digital Manufacturing Solutions. Optimizing threading strategies to high-volume parts by using innovative CNC Cost Saving Thread Milling techniques will yield great increases in efficiency and tool life compared to traditional tapping. Modern MES enables real-time monitoring and optimization of production flow, tool life prediction, and preventive maintenance, maximizing Overall Equipment Effectiveness (OEE).

Case Study: A supplier was tasked with the manufacturing of 50,000 aluminum alloy structural parts for an automotive client. In-depth collaboration on Design for Manufacturability allowed minor modification to be made to the part design to simplify clamping. Using this as a foundation, the associated engineering team developed dedicated multi-part fixtures and optimized high-speed milling tool paths. With the ability to apply strict quality control processes, the supplier, JS Precision, realized a 30% reduction in unit cost while continuing to deliver zero defects, a demonstration of leverage through scale and expertise in engineering.

How to identify suppliers that offer real value beyond just low price?

Value-based selection, instead of a price-based one, would thus be more applicable to sectors like Industrial Equipment Manufacturing where reliability and accuracy are crucial. Supplier Case Studies are extremely useful in determining the relevant experience and problem-solving capabilities of a vendor in your industry. Besides price, other important criteria for evaluation include:

- Technical Communication and DFM Capabilities:

A good supplier will provide helpful DFM input at the quote stage that advises design changes that will improve manufacturability and reduce cost without affecting form, fit, or function.

- Quality Management System:

ISO 9001 certifications are the basic ones; Industry-specific certification such as IATF 16949 for the automotive industry or AS9100D for aerospace provides even further assurance for critical applications.

- Commitment to Sustainability:

An ISO 14001 certification is a proof of a supplier’s commitment to environmental management-a key value in corporate social responsibility for modern companies.

- Physical Validation:

Requesting samples and third-party inspection reports is the most direct method to verify machining quality and consistency. Guidance from established quality authorities can help structure a robust supplier assessment.

From inquiry to delivery, how to prepare for the most accurate quotation and cooperation?

Detailed preparation ensures that the answer to the question “how much does CNC machining cost” is accurate, and there is an efficient collaboration. With the help of a comprehensive inquiry package, one can avoid much back-and-forth communication and obtain the best solution from the supplier.

The Perfect Inquiry Checklist

Ensure the following information is included when requesting a quote:

- 3D Model File: Neutral format such as STEP or IGES is desired for accurate geometry transfer.

- 2D Engineering Drawing: Must be in PDF or DWG format with all critical dimensions clearly given, geometric tolerances (GD&T), surface finish requirements, and any special notes.

- Material Specification: Specify the exact material grade, standard, and any conditions required in the material, such as heat treatment temper.

- Quantity Requirements: State both the current need and anticipated future volumes, this impacts the recommended manufacturing strategy.

- Post-processing and special requisites: Specify if there is a requirement for surface treatment, heat treatment, or any special packaging.

Complete technical documentation forms the first step in getting the exact quote for custom parts through, say, professional CNC Machining Services. Complete preparation provides a sound basis for an effective and reliable relation with a competent supplier.

Conclusion

In brief, control of costs in CNC machining can only be achieved with a deep understanding of its underlying pricing logic and driving factors. By scientifically planning, taking full advantage of economies of scale, and choosing partners with proper technical capability, quality assurance systems, and environmental protection, manufacturing enterprises can optimize costs in all aspects of a product’s life cycle without compromising quality, from prototype development to volume production.

If you need solutions to control critical component costs, I recommend checking out the professional CNC machining service. Uploading your detailed drawings will often bring you a free, detailed quote, which includes valuable DFM suggestions.

Author Bio

The following article is written by an experienced manufacturing content strategist and focuses on providing state-of-the-art insights and hands-on expertise within the context of industrial equipment manufacturing and precision machining.

FAQs

Q: What is the typical MOQ for CNC machining?

A: CNC machining is for prototypes and small-batch production; the MOQs can be as low as one piece. For large-volume production, suppliers usually have an optimal economic order quantity to achieve the best cost efficiency, which should be discussed based on part complexity.

Q: Between stainless steel and titanium alloy, which has a higher cost in CNC machining?

A: Generally, machining cost for the titanium alloy is much higher compared to stainless steel. It is because of the higher cost of raw material, work-hardening property of titanium alloy with low thermal conductivity results in fast tool wear, and hence it requires slower machining speed, that means more time for processing.

Q: At what cost can I get my CNC machined parts without compromising the quality of the parts?

A: It includes early collaboration with the supplier for DFM optimization, relaxing tolerances on non-critical dimensions where functionally possible, selecting more easily machinable materials, and consolidating orders to achieve volume discounts to spread fixed costs thinner.

Q: What is the general lead time for CNC machining?

A: Complexity of part(s), quantity desired, and current supplier capacity. Prototyping as short as 3-5 business days; High-volume production could be several weeks. It is effective to communicate timeline expectations clearly with a supplier.

Q: Besides price, what other qualifications should I consider when choosing a CNC machining supplier?

A: Beyond price, it would be important to validate that the supplier holds relevant industry authority quality system certifications such as ISO 9001, AS9100D, etc. Reviewing their case studies for similar projects and the professionalism of their technical team’s DFM suggestions will also be important.

- Geometric Complexity:

High unit price for small-batch CNC machining? How to reduce unit cost by 91.2% in mass production?

Previous ArticleAli Wong Height, Age, Net Worth & Married Life 2026

Olivia

Olivia is a contributing writer at CEOColumn.com, where she explores leadership strategies, business innovation, and entrepreneurial insights shaping today’s corporate world. With a background in business journalism and a passion for executive storytelling, Olivia delivers sharp, thought-provoking content that inspires CEOs, founders, and aspiring leaders alike. When she’s not writing, Olivia enjoys analyzing emerging business trends and mentoring young professionals in the startup ecosystem.

Related Posts

Add A Comment