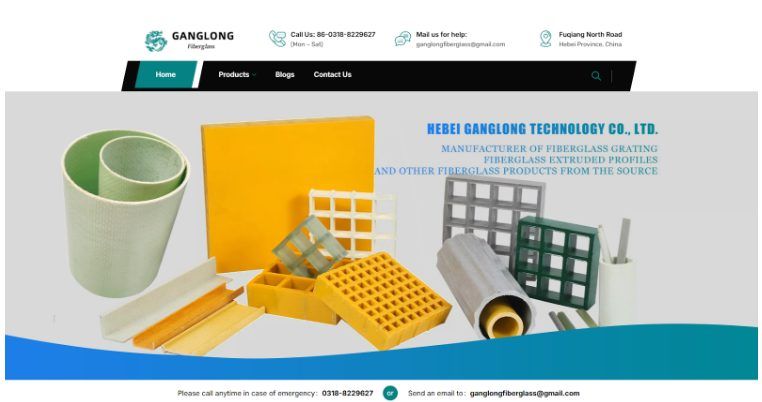

GangLong Fiberglass is a leading manufacturer specializing in high-quality fiberglass products, offering a wide range of reinforcement materials and Chopped Strand Mat. Their production workshop is equipped with the latest technology and machinery, ensuring high efficiency and precision across all manufacturing stages. When working with fiberglass in composite applications, selecting the right reinforcement material is essential for achieving the desired strength, flexibility, and ease of use. Chopped Strand Mat (CSM) is a popular choice, but depending on the application, other fiberglass reinforcements like fiberglass cloth, surface veils, and woven roving may offer better performance. In addition to these materials, GangLong Fiberglass provides complementary products such as fiberglass sheets and cable ladders, which are specifically designed to enhance durability and performance in industrial projects. By incorporating GangLong Fiberglass’ high-quality reinforcements and accessories, you can ensure optimal results in your composite applications. Below, we compare CSM with other fiberglass reinforcements to determine which material is best suited for various applications.applications.

Fiberglass Cloth: Plain Weave and Satin Weave

Fiberglass cloth is a woven fabric made from continuous glass fibers, typically arranged in a plain weave or satin weave pattern.

- Plain Weave: The fibers are woven alternately in a crisscross pattern, providing a relatively strong and stable structure. It offers excellent strength but can be more challenging to handle compared to chopped strand mat. Due to its weave, it can be stiffer and harder to conform to complex shapes, making it less ideal for molds with intricate curves or contours.

- Satin Weave: In satin weave fabrics, the fibers are arranged in a way that creates a smoother surface with less texture. While this weave offers excellent strength and a more refined surface finish, it is harder to handle, especially during the application process. It requires more skill to lay down neatly and bond effectively with resins.

In comparison to CSM, which is easier to handle and requires less experience in working with composites, fiberglass cloth, especially satin weave, provides higher strength but can be more difficult to apply, particularly for larger or complex parts. CSM is more forgiving during application, making it a popular choice for beginners or projects that require a quick, straightforward process.

Surface Veil: What It Is and When to Use It

A surface veil is a thin layer of fiberglass mat, typically around 20 mils thick, that is used to provide a smooth finish to a composite laminate. It is often used as the topmost layer in composite structures to reduce the occurrence of print-through, which is when the texture of the reinforcement fibers (such as those from CSM or woven roving) shows through the surface layer.

Surface veils serve several important purposes:

- Smooth Finish: Surface veils are ideal when the finished surface needs to be free of imperfections, offering a polished, high-quality surface. They are especially useful in applications like boat hulls, automotive parts, or fiberglass sheets where cosmetic quality is important.

- Reduction of Print-Through: By preventing the visibility of the underlying reinforcement layers, surface veils create a pristine finish, particularly in high-visibility areas, such as in marine, automotive, or aerospace components.

- Corrosion Resistance: Some surface veils are specially designed to offer resistance to corrosion, making them suitable for use in harsher environments.

While CSM provides good surface bonding and flexibility, a surface veil is an additional option when the final aesthetic or surface quality is critical, or when print-through might be a concern. For projects requiring a smooth, flawless finish, a surface veil applied on top of CSM can significantly enhance the final product’s appearance and durability.

Woven Roving: When to Choose CSM Over Woven Roving

Woven roving consists of heavy, continuous glass fibers arranged in a woven pattern and is typically used for applications where high strength and stiffness are required. Woven roving provides excellent tensile strength, making it ideal for larger parts or components that need to bear heavy loads. However, it is typically stiffer and more difficult to handle than CSM.

- Strength: Woven roving offers greater tensile and impact strength compared to CSM, making it suitable for high-performance applications that demand maximum structural integrity.

- Ease of Use: CSM, on the other hand, is easier to handle and work with, especially when dealing with complex shapes or smaller projects. It is more forgiving during the application process, and it bonds quickly with resin to form a durable laminate.

- Balance between Strength and Ease of Use: If you need a material that offers a good balance of strength without sacrificing ease of handling, CSM is a better choice than woven roving. It’s particularly useful for small to medium-sized parts, where high tensile strength is not the top priority, and ease of application is more critical.

- Quick Application: For projects that require fast application and simpler processes, such as boat building, automotive parts, or repairs, CSM is often the material of choice due to its simplicity in handling and ability to conform to shapes more easily.

In contrast, if you’re working on high-performance components or structural applications where maximum strength and stiffness are paramount, woven roving may be more suitable, although it requires more skill and precision to lay down effectively.