Manufacturing KPIs (Key Performance Indicators) are metrics used to measure, monitor, and analyse how well production processes perform. They help manufacturers track progress against goals related to quality, output, efficiency, and operational excellence, enabling data-driven decisions and continuous improvement across the production lifecycle.

A common question is, “What are the key KPIs in manufacturing?” Typical examples include Overall Equipment Effectiveness (OEE), Production Yield, Downtime, First Pass Yield (FPY), On-Time Delivery (OTD), Inventory Turnover, and Scrap Rate. Tracking these KPIs improves visibility, highlights bottlenecks, reduces waste, and strengthens overall manufacturing performance.

Top 5 Essential Manufacturing KPIs to Track

These manufacturing KPIs help assess delivery, production, cost, efficiency, performance, quality, and equipment reliability — giving leaders the insight needed to improve operations and stay competitive.

1. Delivery

On-Time Delivery (OTD): Measures how reliably customer orders are delivered as promised.

Formula: (Successful deliveries / Total deliveries) × 100

2. Production

Throughput – Units produced over time

OEE – Overall equipment efficiency

Cycle Time – Time taken to produce one unit

Formulas:

- Throughput = Units produced ÷ Time

- OEE = Availability × Performance × Quality

- Cycle Time = Net production time ÷ Units produced

3. Cost

Manufacturing Cost per Unit: Tracks how much it costs to produce one unit.

Formula: Total production cost / Units produced

4. Efficiency

Production Attainment – Actual vs planned output

Capacity Utilisation – How much of available capacity is used

Formulas:

- Production Attainment = (Actual / Planned output) × 100

- Capacity Utilisation = (Actual / Potential output) × 100

5. Performance

Changeover Time: Measures time lost when switching production runs.

Formula: Net available time – Production time

These KPIs give manufacturers a clear view of delivery reliability, production efficiency, cost control, quality, and equipment health, helping drive continuous improvement and operational excellence.

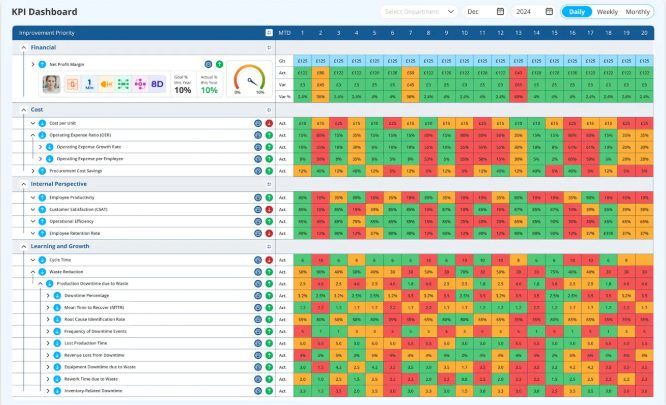

Manufacturing KPI Dashboard Templates – Key Design Tips

A manufacturing KPI dashboard brings all critical production metrics into one clear, visual view. By displaying real-time data on areas such as output, quality, downtime, and delivery performance, it allows production teams and leaders to quickly spot trends, identify issues, and take action before small problems become costly disruptions.

- Define users and goals: Identify who will use the dashboard and what decisions it should support.

- Choose the right KPIs: Focus on manufacturing metrics that reflect performance, efficiency, and improvement opportunities.

- Use clear visuals: Show trends and comparisons with charts like line and bar graphs.

- Keep it easy to read: Use consistent labels and colours to highlight what matters.

- Add smart interactivity: Use filters so users can explore specific KPIs or time periods.

- Review and improve: Regularly update the dashboard based on feedback and business changes.

LTS Data Point – software for manufacturing KPI management

LTS Data Point manufacturing KPI software brings production, quality, and performance metrics together in one live, digital environment, replacing disconnected spreadsheets and manual reports. It gives teams real-time insight into efficiency, downtime, bottlenecks, and quality trends, so decisions are always based on current, reliable data.

Role-based, customisable dashboards allow users to view manufacturing KPIs most relevant to them — from shop-floor measures and maintenance indicators to OEE and quality metrics. Interactive drilldowns, automated alerts, and streamlined reporting help teams detect issues sooner and respond more quickly.

By supporting continuous performance tracking and data-driven decisions, LTS Data Point manufacturing KPI management platform helps manufacturers improve productivity, reduce waste, and maintain consistent operational performance over time.