High-density foam is a leading choice for durability because it packs more material into every cubic foot. Lower-density foams often break down and sag sooner, while high-density foam holds its shape and support for many years. This makes it a reliable base for products that need long life and steady performance, from everyday furniture to industrial gear.

If you want materials that last, learning how high density foam works will help you make better choices.

Here’s how it’s made: manufacturers mix chemicals that expand into a flexible solid. The result is foam that supports more weight, lasts longer, and wears out more slowly. This strength helps prevent “pancaking” in cushions and helps mattresses keep good spinal support for years.

What Is High Density Foam and Why Does It Matter?

High-density foam is defined by how much foam material sits in a set volume. This is measured in pounds per cubic foot (PCF or lb/ft³). That number is a strong sign of how long a product will last and how well it will perform. It isn’t just a label-it points to a material built for long use, where steady support and shape-holding are key.

For example, 2.5 PCF or higher is often called high-density upholstery foam. With more material inside, it handles frequent compression and heavy loads without wearing out quickly. From busy household seating to marine cushions and orthopedic items, density quietly does the hard work so comfort and support don’t fade too soon.

How Foam Density Is Measured

Measuring density is simple: it’s the weight of one cubic foot of foam, shown as PCF (lb/ft³). If a cubic foot weighs 2.5 pounds, the density is 2.5 PCF. A higher PCF means more material in the same space, so the foam is heavier and more substantial.

This number links closely to resilience and lifespan. Checking density gives you a clear read on quality and expected performance. Some high-density foams start around 1.8 PCF or higher, while options like CushionRite Premium Upholstery Foam at 2.8 PCF point to heavy-use readiness.

Density vs. Firmness: Key Differences

Density and firmness are not the same. Density is about how much material is in the foam and strongly affects durability. Higher density generally lasts longer.

Firmness is how the foam feels-soft, medium, or firm-and is measured by ILD (Indentation Load Deflection). A low ILD feels soft; a high ILD feels firm. You can make high-density foam in many ILD levels, so you can have a long-lasting foam that feels soft or firm, based on your comfort goal. This lets you pick the feel you want without giving up lifespan.

How Density Relates to Durability in Foam Products

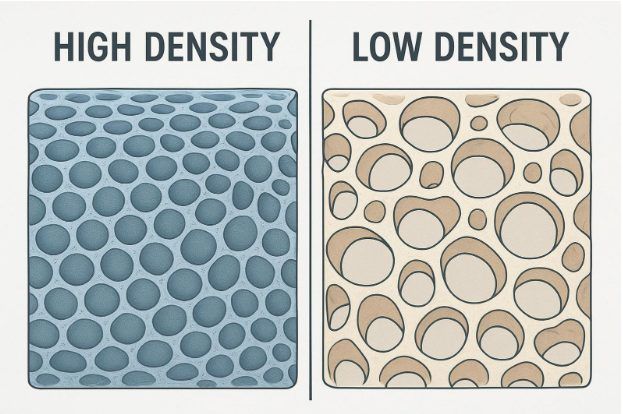

More material per cubic foot creates stronger cell walls inside the foam. That structure helps high-density foam handle daily use and resist sagging, bottoming out, and permanent dents that are common with lighter foams.

Think of a dense sponge versus a loose one. The dense sponge holds its shape and recovers better after squeezing. Foam works the same way. This is why high-density foam is chosen for long-term, heavy-use products where steady support and comfort need to last.

Why Higher Density Improves Foam Lifespan

High-density foam has tighter, stronger, and more connected cells. That network handles repeated compression and rebound well, returning to shape again and again.

Lower-density foam breaks down faster under stress, leading to sagging and permanent impressions. A low-density cushion might need replacing every 1-2 years, while a 2.5+ PCF high-density cushion can last 5-10 years. High-resiliency (HR) foam can go past 10 years with good care. That longer life saves money and limits waste.

Resistance to Sagging and Deformation

Poor-quality foam tends to sag and lose shape, making furniture look worn and feel uncomfortable. High-density foam fights this problem. Its closely packed cells give natural support, so it springs back instead of flattening.

Seats and mattresses made with high-density foam keep their look and support longer, avoiding deep body impressions. Your furniture stays comfortable and fresh-looking for years because the foam holds its form.

Support Under Repeated Use

The real test is daily use. High-density foam performs well here. Its strong structure helps it keep steady support in living room sofas, dining chairs, and commercial seating.

For mattresses, steady support helps with spinal alignment and reduces aches. With high-density foam, a mattress can feel as supportive on day 1,000 as on day one. It’s a smart pick anywhere you need lasting comfort and structure.

What Are the Benefits of Using High Density Foam?

High-density foam offers many clear benefits across many fields. These gains cover comfort, performance, long-term cost, and waste reduction. Choosing it means you get a product that lasts and works well.

From better comfort to fewer replacements, the upsides are easy to see. Here are the main advantages that set high-density foam apart.

Strong Structural Support

Because it has more material per cubic foot, high-density foam carries heavier loads and spreads weight more evenly than lighter foams. This matters for seat cushions where steady support helps prevent pressure points and discomfort.

For people with mobility limits or those who sit for long periods, this steady support helps with posture, makes sitting and standing easier, and can ease back pain. In mattresses, office chairs, and orthopedic products, high-density foam gives a stable base you can count on.

Better Comfort for Long-Term Use

High-density foam is often linked to firmness, but it can also feel soft and plush when made with a lower ILD. You can enjoy a soft feel without giving up durability.

This blend of comfort and staying power is great for mattresses and cushions used every day. The foam keeps its contouring and feel for years, unlike lighter foams that lose comfort quickly.

Extended Product Lifespan

High-density foam helps products last longer. While lower-density foams may need replacing every couple of years, high-density foam can go 5–10 years, and some HR foams can reach 20 years.

That longer life cuts waste and replacement costs. Trusted suppliers such as CHEM-CRAFT support manufacturers in sourcing these long-lasting materials, making it an investment that brings steady performance and lower long-term spend for both buyers and makers.

Better Value Over Time

High-density foam may cost more at the start, but it often saves money over time. Cheaper, low-density foam wears out fast and needs frequent replacement.

Because high-density foam lasts longer and needs less upkeep, the total cost over the product’s life is often lower. For daily-use furniture, mattresses, and commercial seating, the savings and steady performance make it a smart buy.

How Does High Density Foam Compare to Other Foam Types?

Foam terms can be confusing. High-density foam is known for lasting longer, but it helps to see how it compares to other foams. Each type has its own feel, best uses, and life span. A side-by-side look shows why high-density foam often wins for long life and steady performance.

The differences show up in feel, recovery speed, and use cases. This comparison highlights where each type fits best and why high-density foam is a reliable pick for durable builds.

High Density vs. Standard Polyurethane Foam

Standard polyurethane foam comes in many densities and firmness levels. At lower densities (below 1.8 PCF), it tends to wear out faster, which can work for budget projects or seating that doesn’t see daily use.

High-density polyurethane foam (about 2.5 PCF or more) lasts longer because it has more material per cubic foot. Use standard foam for guest seating or occasional use, and use high-density foam for main sofa cushions, everyday chairs, and quality DIY jobs where you want long life.

High Density vs. Memory Foam

Memory foam, first created for NASA, reacts to body heat, molds to your shape, and slowly returns to form. It’s great for pressure relief and is common in mattresses and toppers.

But memory foam, especially at lower densities, can be slow to recover and may feel warm. High-density memory foam (5 PCF or more) gives better support and life, but high-density polyurethane foam usually rebounds faster and suits core support in cushions and furniture. Many mattresses use a high-density polyfoam base for support with a memory foam layer on top for contouring comfort.

| Foam type | Typical density (PCF) | Feel & recovery | Best use | Expected durability |

| Standard polyurethane | < 1.8 | Fast bounce, light | Occasional seating, budget builds | Short |

| High-density polyurethane | 2.5+ | Quick recovery, steady support | Daily-use cushions, core support | Long |

| Memory foam | 3-5+ (5+ for high-density) | Slow response, body-contouring | Comfort layers in mattresses | Varies with density |

Performance in Different Applications

The right foam depends on where and how it’s used. High-density foam stands out in many areas:

- Upholstery: A go-to choice for busy sofas, dining chairs, and commercial seating where resisting sag and holding shape matter a lot.

- Mattresses: Gives needed support and long life so comfort and spinal alignment last for years.

- Marine & Automotive: Closed-cell versions resist water, and the foam keeps shape under load, making it a fit for boats, cars, and RVs.

- Orthopedic Products: Provides firm, steady support for cushions, wedges, and bed inserts to help reduce pressure points.

Lower-density foams can work for occasional-use items or tight budgets, while memory foam shines as a comfort layer where pressure relief is the goal. High-density foam remains a strong pick across many tough settings.

What Factors Affect the Longevity of High Density Foam?

Density is important, but other factors also shape how long high-density foam will last. These include the exact density, foam grade, build quality, and how the foam is used and cared for.

Knowing these points helps buyers and makers get the most life from their foam. Here are the main factors that influence long-term performance.

Density Ratings: What the Numbers Mean

PCF (pounds per cubic foot) is the clearest signal of potential lifespan. Higher PCF means more material and usually longer life. For upholstery, 2.5 PCF or higher is often considered high-density and performs better than lighter options.

- Medium-High Density (2.5-3.0 PCF): Good for everyday furniture, balancing life span and cost.

- High Density (3.0-3.5 PCF): Great for daily sofa cushions and other loads that need steady support.

- Ultra-High Density (3.5+ PCF): Premium grade for commercial use or places that need extra durability.

These numbers reflect the foam’s inner build and its ability to resist wear and hold shape over time. When buying, check the exact density so you get the quality you expect.

The Role of Foam Grades and Quality Standards

Density is only part of the story. Build quality and foam grade matter too. High-Resiliency (HR) foam is a high-quality type with density of 2.5 PCF or more and an advanced cell structure that bounces back faster and holds shape longer than standard polyurethane at the same density.

Certifications like CertiPUR-US help show the foam meets standards for content, emissions, and durability. They also indicate the foam is made without certain harmful chemicals. Buying from reputable makers with tight quality control helps you get foam that’s both dense and well-made, which supports a longer life.

Influence of Usage and Maintenance on Durability

How foam is used and cared for can shorten or extend its life. Heavier users and frequent use compress foam more and can shorten lifespan. A family-room sofa, for instance, will wear faster than a guest-room chair.

Good care helps: rotate cushions to spread wear, keep foam clean, and protect it from heat and direct sun. Strong upholstery methods and durable cover fabrics also reduce outside wear, letting the foam inside do its job for longer.

Are There Any Drawbacks or Limitations to High Density Foam?

High-density foam excels at durability and support, but it has a few possible downsides, depending on the use, comfort preferences, and budget. Seeing both sides helps you pick the right material for the job.

These points aren’t deal-breakers, but they are worth weighing during selection so you get the best fit for your needs.

Potential for Increased Firmness

High-density foam can feel firmer, especially if it’s made with a higher ILD. People who like a very plush, sink-in feel may find some high-density foams too stiff.

This can matter in senior living spaces, where softer cushions may be preferred. While high-density foam offers great support, some users may want a softer ILD. The good news: you can choose high-density foam in softer ILDs to get both comfort and long life.

Weight and Handling Factors

High-density foam is heavier than lighter foams of the same size. This can make furniture heavier and harder to move or rearrange. Shipping and handling may also be more involved.

DIY users may need better tools. A basic knife may not cut cleanly; a foam saw or similar tool often works better. Planning for weight and cutting needs can make projects smoother.

Cost vs. Long-Term Value

High-density foam usually costs more upfront than lower-density options. That can stretch a budget. But the longer life and steady performance often cut replacement costs over time.

Replacing a low-density cushion every 1-2 years can cost more in the long run than buying a high-density cushion that lasts 5-10 years or more. The higher starting price often leads to lower total cost and less hassle over the life of the product.

Key Takeaways: Choosing High Density Foam for Lasting Durability

Across foam types, density is the best single sign of how long a product will last, how well it resists sagging, and how well it keeps support. Picking high-density foam is a smart move if you want long life and steady quality.

This strong material is the base for items that face daily use, from family sofas to marine seating. By choosing higher density, you help your cushions, mattresses, and other foam items stay comfortable and supportive for years. Good quality lasts.